The VACON® NXP and VACON® 100 drive series are now embedded with condition-based monitoring functionality.

This allows you to use your drive as a smart sensor to monitor the condition of your motor and application. It will help you detect early issues and find solutions before they have an impact on the process.

With condition-based monitoring, internal sensors monitor activity beyond the drive, gathering data from multiple sources and generating vital, instantaneous insights.

The CBM compliance system includes motor stator winding condition monitoring, overload monitoring and vibration monitoring via an external sensor:

During monitoring system is capable detects, a short circuit or imbalance between the motor windings.

If the windings are severely damaged, the frequency converter current protection is also activated, which in turn stops the motor.

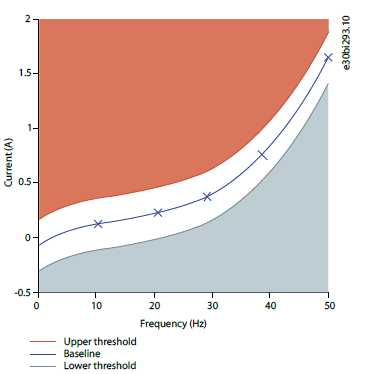

The function learns the load curve of the application and detects whenever the load moves above or under the baseline level.

The function is useful fault detection in various applications with passive load:• Fouling, sanding, broken impeller or wear-out of pumps • Clogged filters and leakages in ventilation systems • Friction in machines

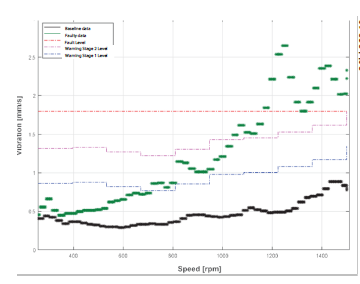

With the help of external sensors, the drive can monitor the level of vibration in the motor.

Vibration affects engine control and can cause engine failure. During the monitoring, engine inconsistencies and wear are detected early, which can be caused by, for example, the destruction of the mechanical parts of the engines.

Napal AS

Nõmme tee 95 / Tüve 22a, 11317 Tallinn

Tel: +372 627 4700

Fax: +372 627 4710

E-post: napal@napal.ee

© 2024 Napal AS